PART 1

How To Unlock Production Potential

In Your Business Using Our Business Improvement Programme

If you are a leader in an operating department on a mine site, you likely have the responsibility to deliver safety, production and/or cost outcomes. A business improvement (BI) programme can help you deliver beyond these desired outcomes while providing additional benefits to you and your team (discussed in our next part of the series).

Reactive vs Proactive

A BI programme can be used to react to a change in conditions; the current world economy and its impact on metal prices is certainly a great example. It can be also be used proactively to extend delivery of desired outcomes beyond the intended goals (for example, annual production targets). The process to conduct a BI programme reactively or proactively is generally the same, however, you are more likely to be under pressure when reacting to a new set of conditions (whether externally or internally imposed on you). Proactively undertaking a BI programme allows time to get it right upfront.

Some examples where BI programmes have generated improved outcomes are discussed below.

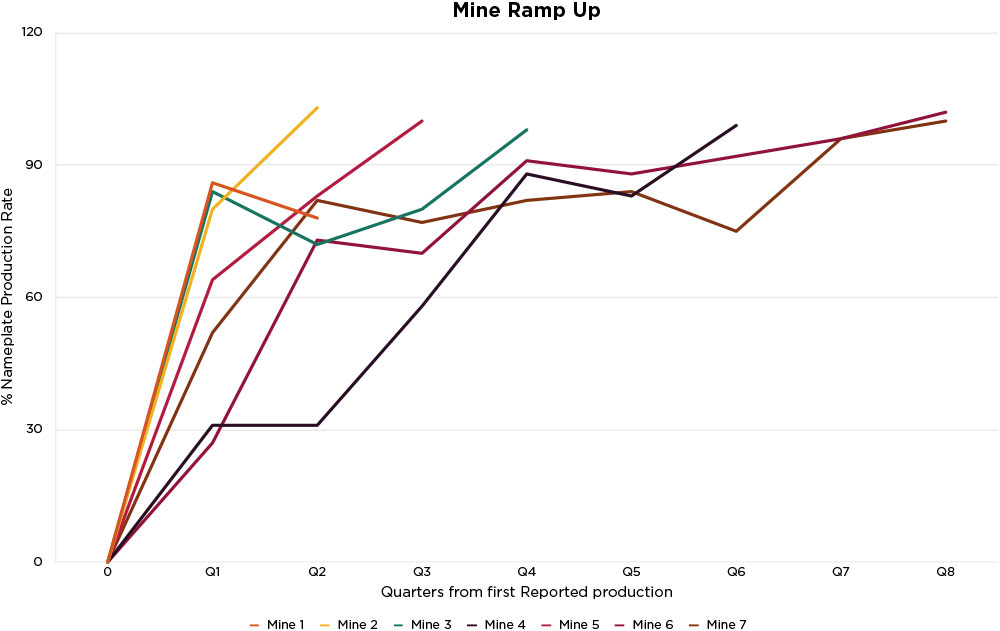

New Mine Ramp Up

It is well understood that a new mine does not immediately start operations at nameplate production. The “ramp-up curve” is the comparison made of an operation to determine if the return on capital invested in a mine will be returned within a reasonable amount of time. Public information from recent Australian mine start-ups shows a large difference in time to full nameplate capacity.

If your operation is beyond a year from reported production and still not at nameplate production, it may be time to employ a BI programme.

Similarly, if your production plans for mine start-up suggests a long start-up, a BI programme focused on operational readiness may reveal key actions in bringing forward production.

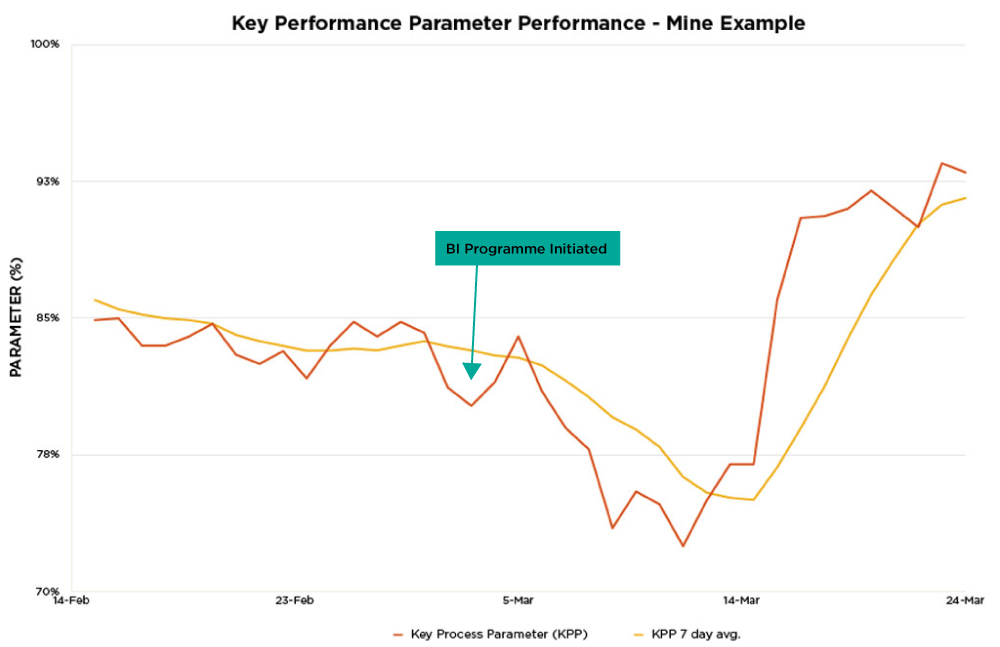

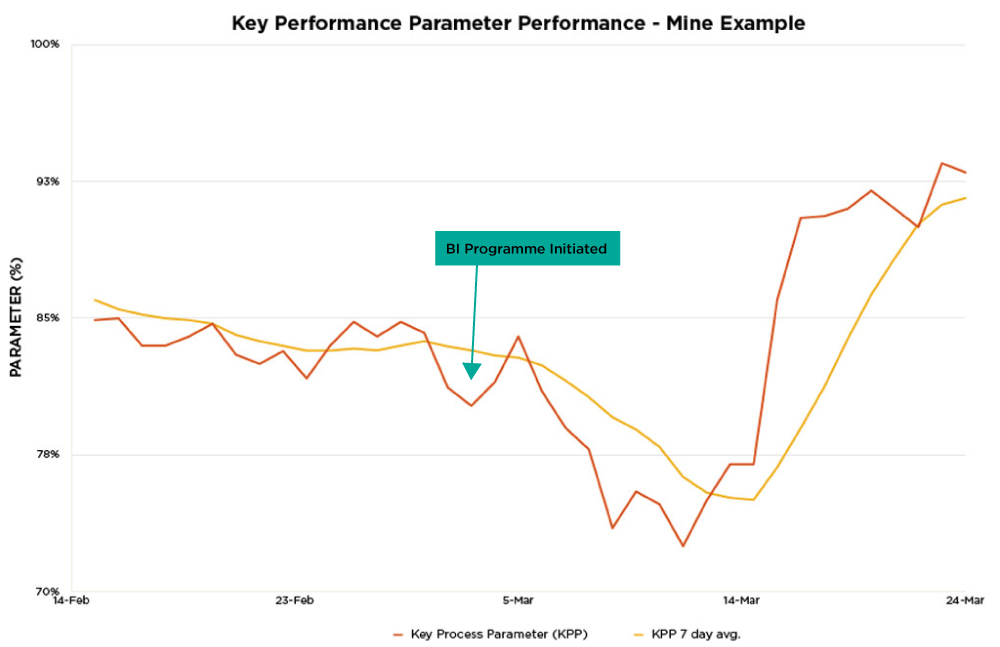

Significant Production Losses

Sometimes the wheels fall off and it’s not clear whether a single large event or several small events have culminated in a process loss. A well-executed BI programme will quickly identify the root cause of your issue and execute the necessary actions to rapidly recover performance, stabilise the performance at the improved rate, and embed the practices that consistently produce the desired results. Our example below is discussed in subsequent parts of this Business Improvement series.

Reducing Exposure To Risk

As an operations leader delivering safety, production and cost outcomes, you will face risks to delivering on these targets on a regular basis. A way to proactively manage these is to leverage your business’ risk management framework in order to safeguard the operation from undesired material events. If your risk management framework has identified several areas of exposure due to risk control weakness, a BI programme can help to systematically strengthen your site’s control of risks to plan delivery.

If you’re executing a BI programme well, you’re likely achieving new levels of performance. It’s easy to demonstrate improvements to safety, production and cost outcomes, but there are additional benefits that will come from a well-executed BI programme.

Development Opportunities

A BI programme that incorporates a cross-section of disciplines on your site is a great opportunity to push that promising employee out of the comfort zone to work on skills they would not normally get to practice in their typical discipline. It’s an opportunity to demonstrate out of the box thinking, financial understanding of the business, influencing capabilities or team leadership, among many other things.

Silo Breaking

A BI programme that incorporates a cross-section of disciplines on your site will have to work together to achieve the programme goals. The right BI programme will help team members start working together with others outside of their usual team. You can expect in future to see cross-functional problems being solved without having to bring different parties together yourself.

A Platform

The BI programme will be undertaken to meet a business need, and the best supported BI programmes communicate the programme site-wide to support engagement with the BI team. As a site operations leader, when you’re investing in the BI programme, you’ve got a platform to continually talk your targets. As you’re celebrating the success of your BI programme, the platform remains to keep talking to your targets.

Isolation

There may be times where temporary measures are required to be enacted in a BI programme to achieve a business objective, such as a freeze on capital expenditure. These are usually done in “tough times” and can be notoriously difficult to execute well. By encapsulating the temporary measures in a BI programme, it allows site leadership to allay fears that the hard practices will be practiced in an ongoing manner.

In the previous article, we introduced a mine with a significant process interruption. A hindsight review of the problem might suggest an easy solution was implemented to not only respond to the severe drop in performance but improve performance beyond previous outputs in such a rapid manner. This improvement, however, was only achieved through a deep understanding of the problem, which is fundamental to a successful BI programme.

Technical Understanding

You’ve probably heard of techniques like 5-why or root cause analysis. These are among many different processes that can be used to understand your issue. They all require the same thing; a technical expert. As much as a BI programme benefits from a multi-disciplinary team, dissection and presentation of information about the problem in a digestible manner are fundamental to a successful BI programme. A BI programme chasing the wrong cause of the issue cannot implement the right actions. If you don’t have the expert on your team, you need to seek that expert.

Benchmarking

What does good look like? If this is not known, it cannot be achieved. Benchmarking is an important step to set appropriate targets for your Business Improvement programme. Benchmarking provides the certainty that the targets are not too low or too high.

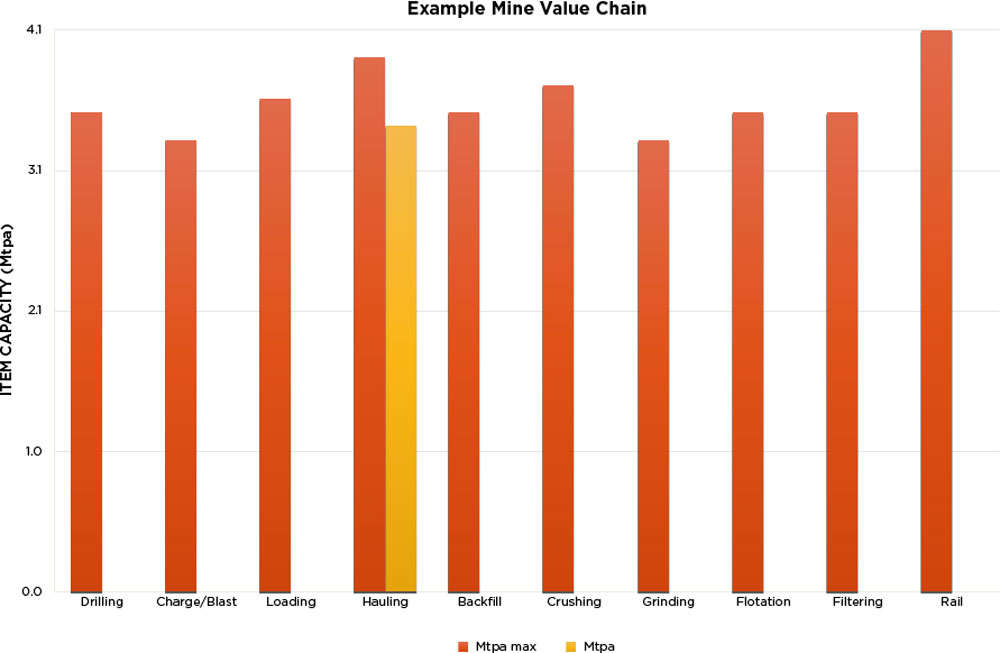

Understanding The Value Chain

A significant impact on one area of the business may mean you’re no longer achieving planned production rates. It may not mean that the business will be impacted materially, and it may be a waste of resources to try to fix the problem immediately. An understanding of the mine value chain is critical to make the right decisions.

Consider the example below

Suppose a truck in the mine fleet has a catastrophic failure and is no longer available to haul. A quick look across the value chain shows that the reduction in haul capacity cannot impact the concentrator as the grinding process is the value chain bottleneck. Efforts to expedite repair on the truck at an increased cost may be wasted if it would not materially improve the overall value chain.

Resolve Mining Solutions has the technical experts that cover the whole of mine operations and can help you dissect your operations, and set the right targets for your Business Improvement programme. For more information complete the below contact form, email [email protected] or call 1300 220 440.