PART 4

How Effective Planning Turns Operations

Around In 3 Weeks

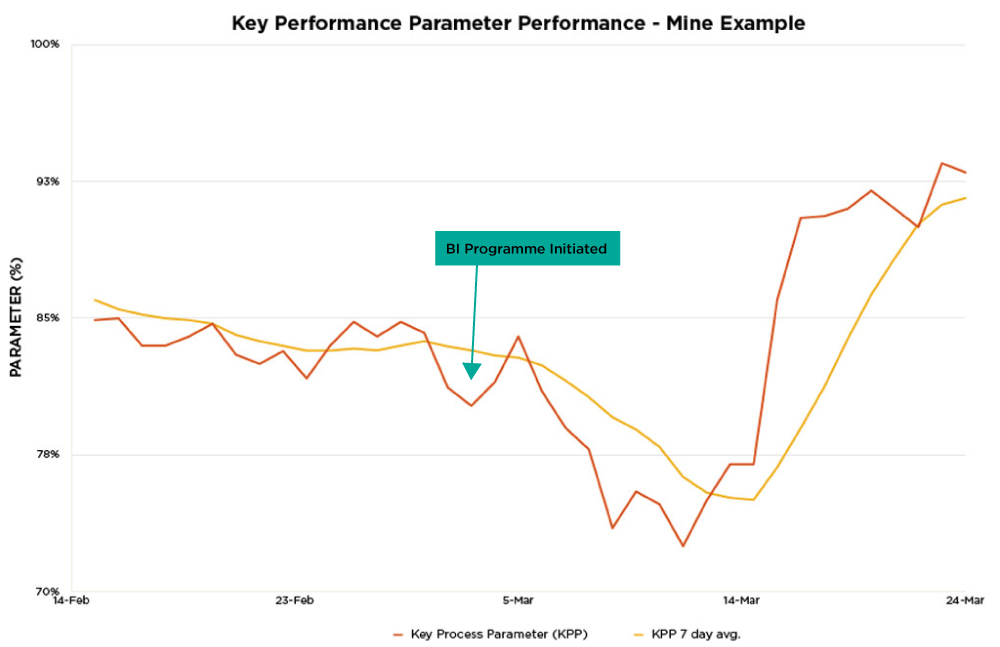

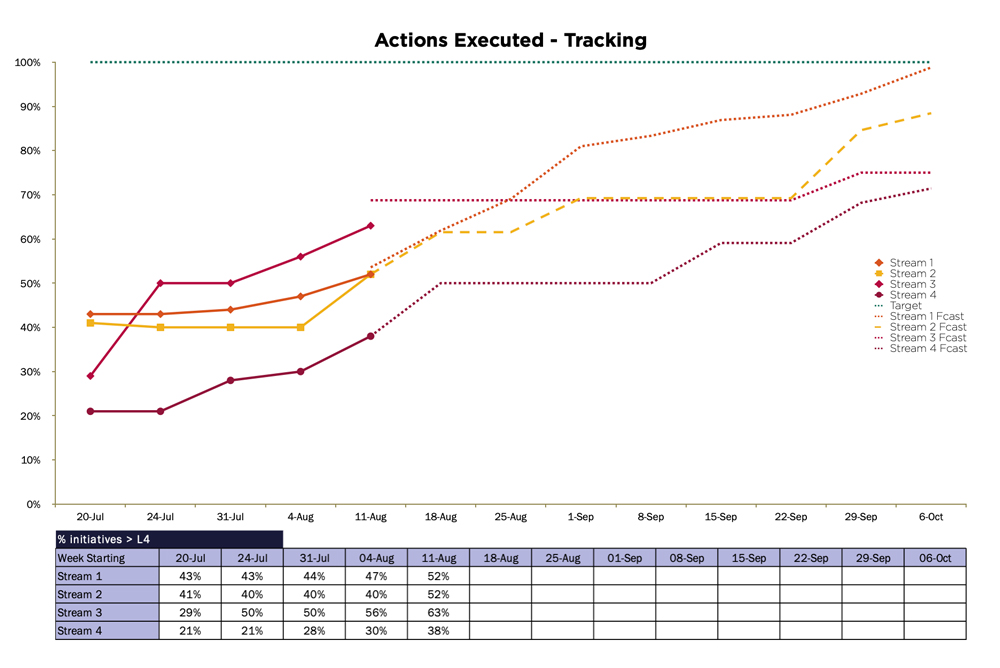

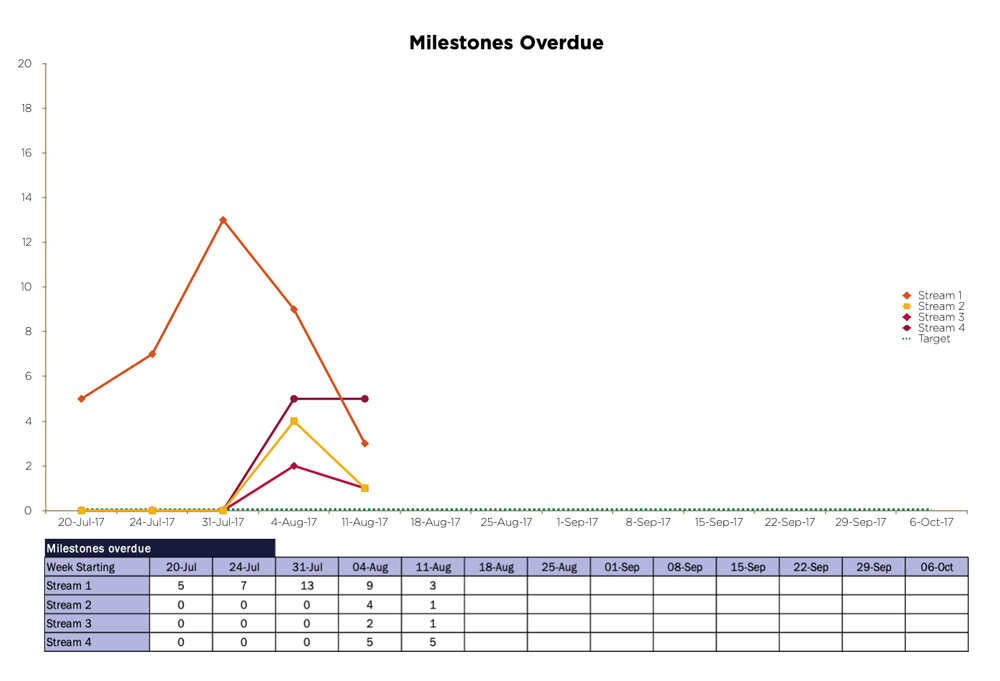

Once you’ve used your technical experts to understand the issue(s) at hand, it’s time to take steps to remedy them. Referring again to our previous mine example, the mine with a significant process interruption. The BI programme had in excess of 100 actions that needed to be completed.

The programme was given a condition that any changes made to operation must be sustainable. The results above show that within a month the immediate issue was addressed. The programme in fact lasted for close to 8 months to deliver the sustained results. To achieve this, the programme divided the actions into phases so that the BI team members completed the actions in a coordinated manner. The programme was broken into 3 phases of actions; those to immediately recover performance, those that stabilise the performance at the improved levels, and the final stages that ensure that the practices are engrained in site practices/culture.

The Importance Of The Embed Phase

The embedding phase is often forgotten as it is seen as the “boring” part of the improvement programme. This example shows quick improvement as if the problem was “easy”, however a review of a historical review of the same parameter showed that the high performance has been achieved in the past and subsequently failed. Evidently, sustainable practices were not in place.

Figure – Mine example historical parameter performance

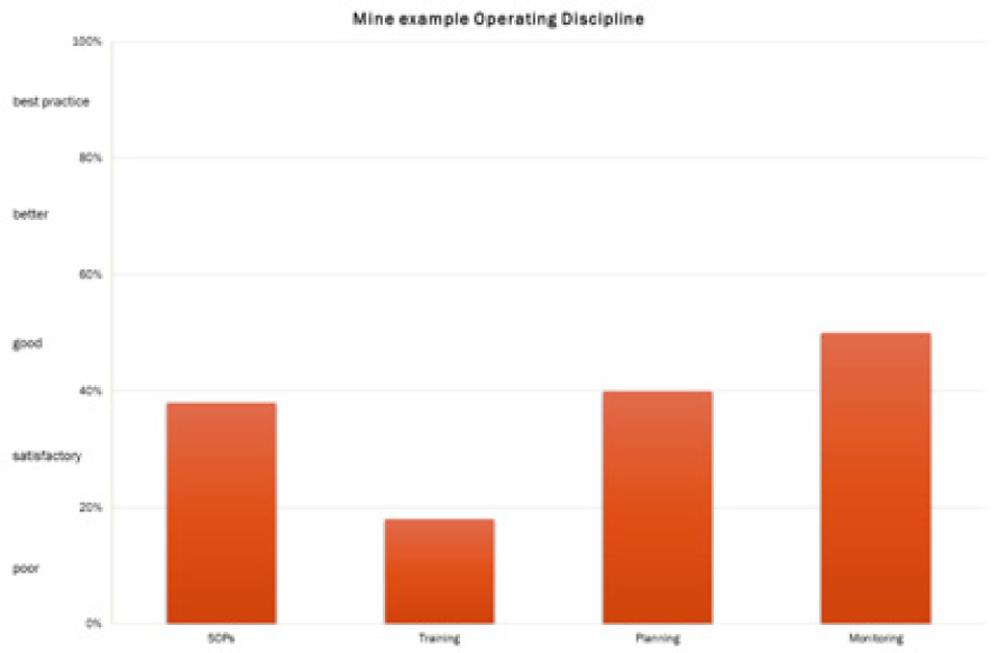

A review was conducted of the SOPs for the production facility, their implementation (through training) as well as how technical staffed planned and monitored the key processes to achieve high performance. Despite clearly being able to improve performance without these items in place, the review provided a clear impetus for ensuring the embed phase was undertaken to sustain production in the long term.

At this point in the in your BI programme, you’re executing actions and hopefully starting to realise some noticeable improvements. It’s natural at this stage to ask; Is the programme delivering outcomes as quickly as it should?

Mindsets

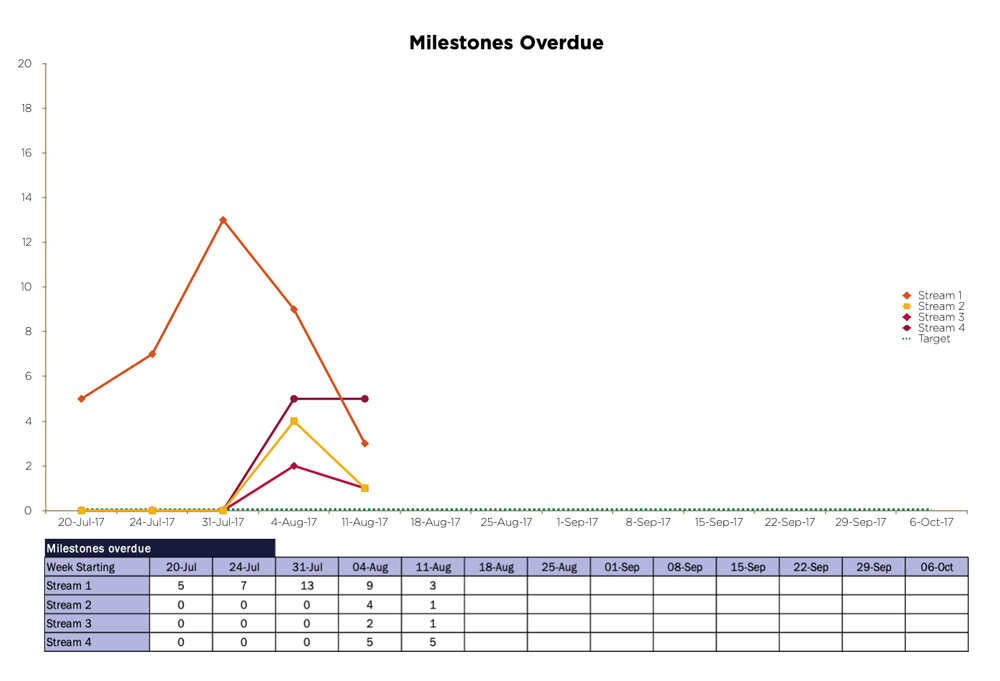

A BI programme workstream leader must be keeping track of the delivery of actions within the programme. They must be able to articulate when actions are to be completed and when they will be delivering the intended outcomes.

Anyone who is overseeing the BI programme must be mindful of workstream leads and their teams to ensure that they can and do deliver on the actions in the BI programme, and address any performance issues promptly. A view of action completion and delivery of outcomes to plan can provide a view as to where this coaching/mentoring needs to take place.

Anyone who is overseeing the BI programme must be mindful of workstream leads and their teams to ensure that they can and do deliver on the actions in the BI programme, and address any performance issues promptly. A view of action completion and delivery of outcomes to plan can provide a view as to where this coaching/mentoring needs to take place.

Programme performance The BI programme leaders must also ensure that the programme is delivering the intended benefits. It is one thing to be completing actions on time; it’s another to have the actions being completed that provide the outcomes required. Action completion tracking, as well as monitoring of the intended outcomes, go hand in glove in a successful BI programme.

Resolve Mining Solutions can help you ensure you are tracking the right outcomes in your Business Improvement programme.

When you’ve completed a successful BI programme, the natural inclination is to continue to utilise the tools that have generated the successful outcomes. Business Improvement often becomes “Continuous Improvement” often only to later be left by the wayside as the delivery of a benefit to the business becomes unclear. There are two other complementary practices that can be integrated into site processes to ensure that your site continues to reap the benefit of BI processes; Risk Management and Change Management. This trio of business processes can help sustain high whole-of-operation performance.

Change Management, Risk Management and Business Improvement Working Together

It’s likely that you’ve worked with at least one of these systems in the past. If implemented right, they would have generated some positive outcomes. There are important elements of Risk Management and Change Management that should be considered when developing these processes for your operation.

Good Practice Elements Of Risk Management

- Regular risk register review by site management (annually)

- Risks and their controls are appointed single owners to be held accountable for their performance

- Regular review of risks and their controls by risk and control owners

- Actions to improve risk and their controls are tracked and managed

- New unwanted events prompt the review of the risk register, risk and control design

- Findings from Insurance audits are reflected in the risk management process

Good Elements Of Change Management

- Roles are assigned to individuals to manage change management

- Tailored training is provided to the various roles and the individuals using change management

- Changes are risk assessed using multi-disciplinary teams

- Electronic records of changes are kept in a data management system

- Approvals are recorded/maintained within the same electronic system

How The 3 Processes Intersect

When the risk management review provides the ability to take a snapshot of risk management gaps across an operation, this provides an ability to package risk reduction activities into BI programmes. Using the BI process delivers improved outcomes, thereby reducing your site’s exposure to unwanted events.

It is likely that the risk management process would nominate Change Management as a control to manage some elements of site risks. A savvy Change Management control owner should soon recognise the benefit of ensuring all unwanted event risks are prompted by the change management risk review process. If BI changes are taken through Change Management and are subject to the Risk Management lens, you’re going to be implementing changes that add to your bottom line without increasing your risk exposure.

With the 3 systems designed well and implemented appropriately, they should seamlessly feed into and off of each other. The benefits of the systems will be improved and no longer would it be difficult to articulate why the systems must be maintained for your operation. Talk to Resolve Mining Solutions today about how to structure these important business processes at your site.

Resolve Mining Solutions has the technical experts that cover the whole of mine operations and can help you dissect your operations, and set the right targets for your Business Improvement programme. For more information complete the below contact form, email [email protected] or call 1300 220 440.